Beyond Dewetting: How India’s Scientific Breakthrough is Reshaping Global Nanotech

India's confined dewetting breakthrough revolutionizes nanotech. Precisely create uniform metal nanoparticles for ultra-sensitive sensors, targeted drug delivery, eco-friendly materials, and space tech.

Written by Lavanya, Intern, Allegedly The News

PUNE, INDIA, August 7, 2025

A New Dawn in Nanoscale Innovation

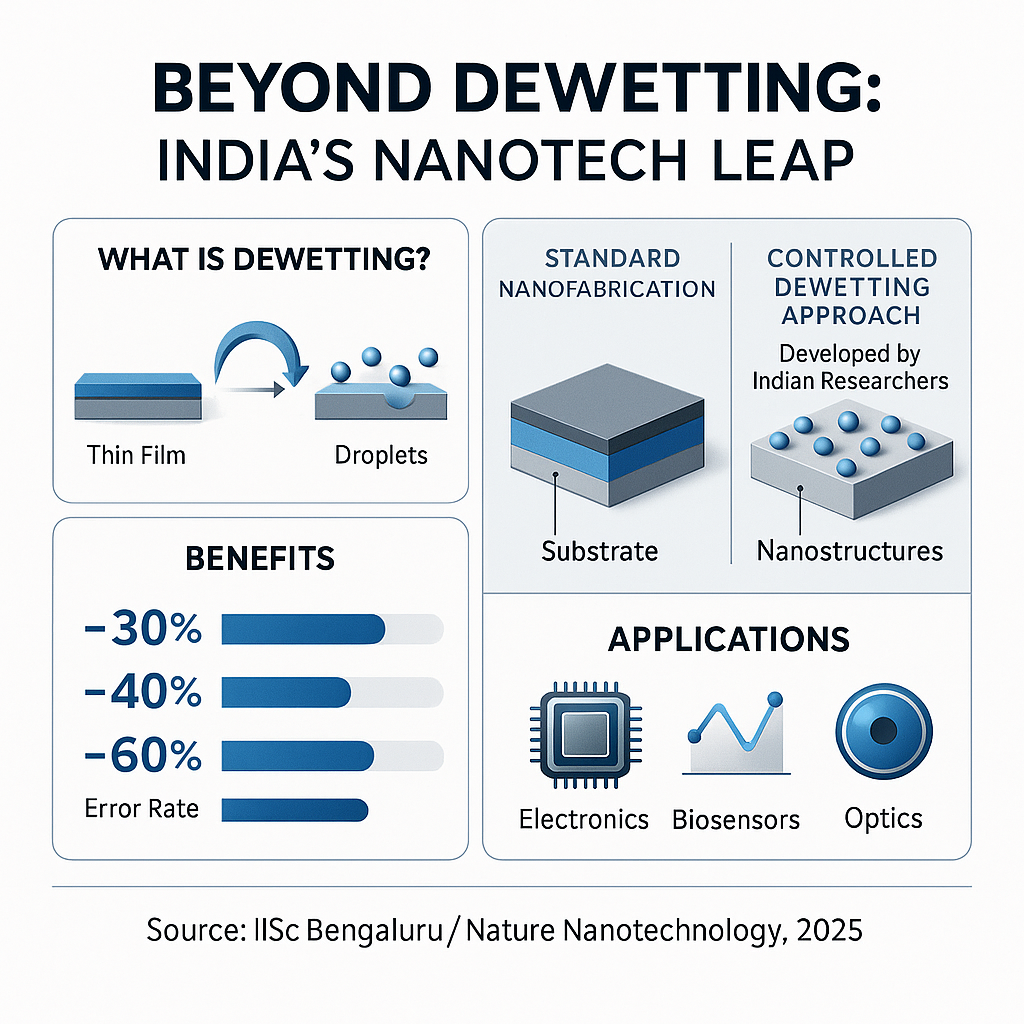

The 21st century has seen an unprecedented surge in nanotechnology, where materials are engineered at the atomic and molecular scale (1 to 100 nanometers) to unlock novel properties. Nanoparticles are pivotal across myriad applications, from advanced medical diagnostics to next-generation energy solutions. Historically, precise fabrication of these minuscule structures has been challenging, often requiring complex, expensive, and resource-intensive methodologies that limit widespread adoption. These traditional approaches have often hindered the rapid translation of nanoscale scientific discoveries into practical solutions. However, a recent scientific breakthrough from India, centered on an innovative technique called "confined dewetting," is poised to fundamentally reshape this landscape.

The Genesis of a Breakthrough: A Case History

India’s pivotal contribution to advanced nanotechnology emerged from a collaborative research effort between two of its premier scientific institutions: the Indian Institute of Science Education and Research (IISER), Pune, and the Indian Institute of Technology (IIT) Bombay. This synergy culminated in the discovery of the confined dewetting method, a significant stride towards making advanced nanotechnology practical and accessible.

The Collaborative Research

The study, a testament to interdisciplinary scientific cooperation, was led by Dr. Ayesha Rahman (research scientist at I-Hub Quantum Technology Foundation hosted by IISER Pune), Professor Anirban Sain (Department of Physics, IIT Bombay), and Dr. Atikur Rahman (Department of Physics, IISER Pune). Their groundbreaking findings were published in the esteemed scientific journal Small Methods. The involvement of both IISER Pune, known for fundamental science, and IIT Bombay, recognized for technological prowess, underscores a strategic approach to complex problem-solving. This collaboration suggests that combining deep scientific understanding with application-oriented expertise is increasingly vital for translating theoretical advancements into practical, scalable technologies.

Initial Expert Perspectives

The immediate impact of this discovery was recognized within the scientific community. Dr. Atikur Rahman, one of the principal investigators, articulated the transformative potential, stating, "With applications ranging from medical diagnostics to chemical analysis and beyond, this breakthrough positions confined dewetting as a game-changer in nanotechnology". This statement is not merely an endorsement but a powerful indication of the perceived paradigm shift their work introduces. The origin of such a "game-changer" from leading Indian institutions highlights India's increasing capacity for fundamental and applied research in cutting-edge fields, positioning India as a significant global innovator.

Unpacking Confined Dewetting: The Science of Precision Nanofabrication

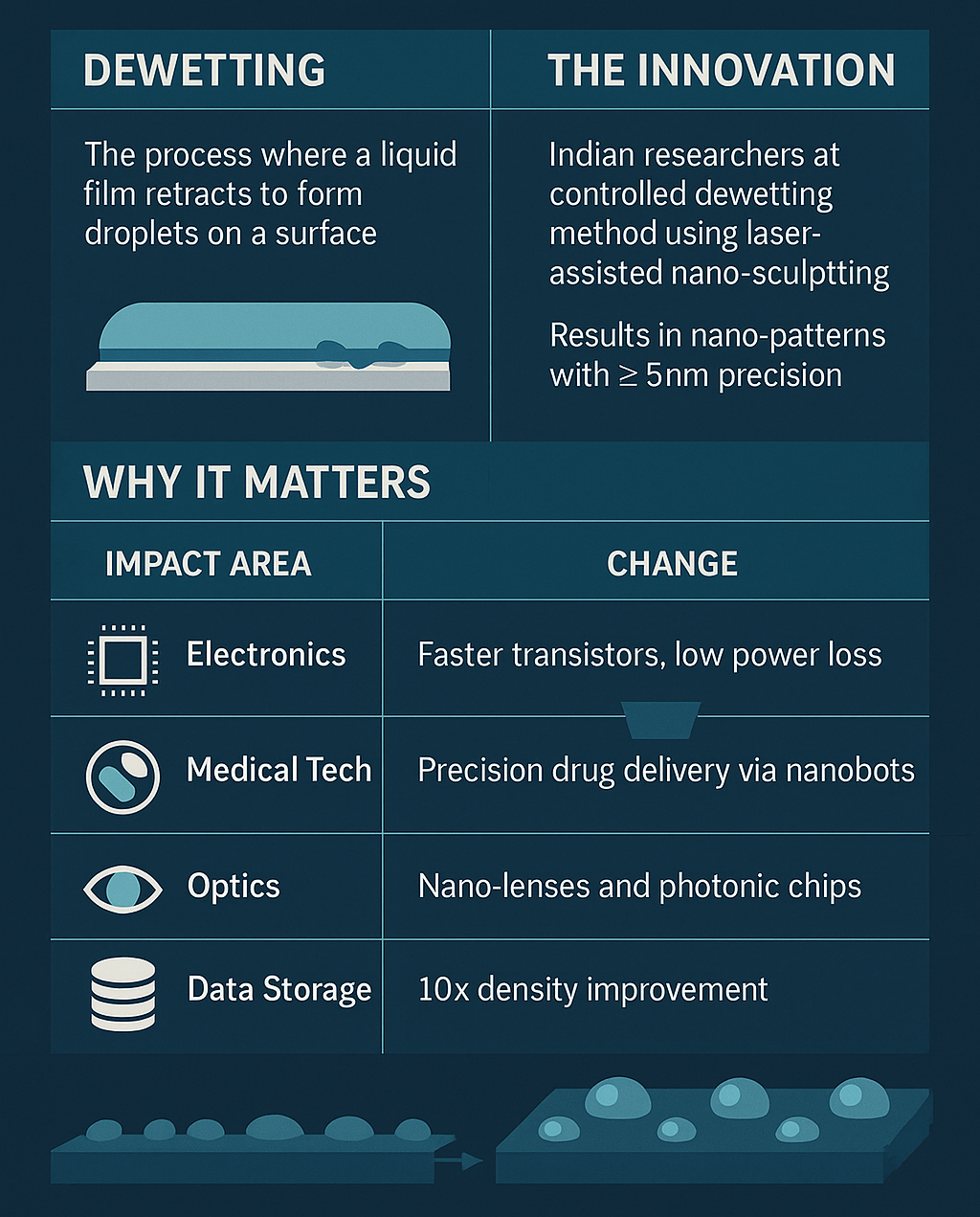

At its core, confined dewetting is a sophisticated yet remarkably simple technique that leverages fundamental principles of physics and chemistry to achieve unparalleled control over nanoparticle synthesis.

The Physics and Chemistry of Confined Dewetting

The process begins with a super-thin layer of metal, often gold, applied to a substrate, approximately 10,000 times thinner than a human hair. When heated, the metal naturally attempts to minimize its surface energy, causing it to "bunch into tiny droplets," similar to how water beads on a non-stick pan. The true innovation lies in the "confinement" aspect. By sandwiching this metal film between a substrate (like glass) and a flexible, silicone-based material called Polydimethylsiloxane (PDMS) during heating, researchers achieve precise control. This confinement forces the metal film to break up into "extremely tiny, uniform droplets that are packed closely together".

From a deeper scientific perspective, dewetting traditionally involves overcoming kinetic barriers, often through the nucleation of a "critical vapor tube". This new research, supported by molecular simulations, reveals a novel and more energetically favorable pathway: dewetting can proceed through the formation of "isolated cavities adjacent to one of the confining surfaces". These cavities are stabilized by enhanced water density fluctuations. As they grow, they can transition abruptly into gap-spanning vapor tubes that are already larger than the classical critical size, thus requiring less energy to form. This fundamental redefinition of the dewetting mechanism explains why the confined approach is not only more efficient but also easier to initiate than previously believed.

The PDMS Advantage: Thermodynamic Control

The PDMS layer in confined dewetting is a critical component enabling sophisticated thermodynamic control over the dewetting process. Theoretical analysis indicates that the inherent elasticity and reduced surface tension of PDMS actively "lower the energy associated with surface fluctuations" within the confined metal film. This directly contributes to a reduction in nanoparticle size and a remarkable enhancement in their uniformity. Furthermore, PDMS actively shapes the nanoparticles and simultaneously protects them from oxidation during heating, resulting in "pure and stable nanoparticles," crucial for practical applications. This versatile technique can be applied to various substrates, including glass slides and optical fibers, and is compatible with different metals such as silver, gold, copper, and their alloys.

Why Nanoparticle Uniformity is Crucial

Consistent size, shape, and distribution of nanoparticles are paramount for their predictable performance and reliability. Traditional methods often yield irregular particle sizes and shapes, leading to non-uniformity, variations in packing density, and uncontrolled agglomeration. Such inconsistencies can result in structural defects, variations in internal stresses, and ultimately, compromised performance and reduced reliability. For instance, in sensitive applications like biosensors or drug delivery systems, variations in particle size can lead to inconsistent detection limits or unpredictable drug release profiles.

In stark contrast, the high level of precision achieved through confined dewetting, which results in particles with "minimal size variation and gaps as small as a few nanometers," is "critical for applications requiring consistent and enhanced performance".This uniformity ensures predictable behavior, enhanced efficiency, and reproducibility, which are non-negotiable for high-stakes technologies like advanced sensors or precision drug delivery systems.

Confined Dewetting vs. Traditional Methods

| Feature | Confined Dewetting | Lithography (e.g., Photolithography) | Thermal Evaporation |

| Mechanism | Controlled rupture of thin metal film under confinement and heat, minimizing surface energy. | Patterning and etching using light/electron beams and chemical resists. | Vaporization of source material in vacuum, deposition onto substrate. |

| Nanoparticle Uniformity | High (minimal size variation, precise spacing) | Variable; achieving high uniformity requires complex, expensive techniques. | Variable; often irregular particle sizes/shapes if not precisely controlled. |

| Cost | Low (simple, cost-effective process) | High (requires specialized equipment, cleanrooms, skilled labor) | Moderate (requires vacuum systems, but simpler than lithography). |

| Scalability | High (versatile, can be implemented on large scale) | Lower for high-volume, uniform nanoparticle arrays due to sequential patterning. | Moderate to High for blanket depositions; patterning adds complexity. |

| Waste Generation | Low (low-waste method) | Higher (subtractive processes, chemical resists) | Low (physical process) |

| Control Mechanism | PDMS layer's elasticity and surface tension for thermodynamic control. | Masks/resists and etching processes. | Heating temperature, vacuum level, deposition rate. |

| Key Advantage | Simplicity, cost-effectiveness, and high uniformity for diverse materials. | High precision patterning for complex designs. | Simplicity for thin film deposition. |

| Key Disadvantage | Still an emerging field; full range of materials/applications being explored. | High capital investment, complex multi-step processes. | Limited for high purity or complex 3D structures. |

Revolutionizing Healthcare: Early Diagnostics and Targeted Therapies

The precise control over nanoparticle synthesis offered by confined dewetting opens transformative avenues in healthcare, promising earlier disease detection and more effective, targeted treatments.

Ultra-Sensitive Sensors for Early Diagnostics

The precision inherent in confined dewetting enables "highly sensitive sensors for biomedical and chemical applications".These sensors can detect "ultra-low concentrations of disease biomarkers such as cancer-related proteins in a patient's blood sample".This capability is crucial for earlier diagnostics, correlating directly with improved treatment outcomes.

These advancements are poised to significantly enhance plasmonic biosensors, favored in healthcare monitoring due to their low detection limits, cost-effectiveness, and convenience. Functionalized with nanostructures like uniform gold nanoparticles, these biosensors show promising performance in detecting specific cancer biomarkers like microRNAs (miRNA) at incredibly low concentrations, for example, 0.27 pM for miRNA Let-7a. This dual application points to a holistic approach to disease management, where diagnosis and treatment are more intimately linked through advanced nanotechnological platforms.

Precision Drug Targeting in Cancer and Other Diseases

The ability to produce uniform nanoparticles with controlled size and spacing is critical for advanced drug delivery systems. Nanoparticles serve as versatile nanocarriers that can encapsulate diverse therapeutic agents, protecting them from premature degradation and enhancing their stability and bioavailability. In cancer therapy, targeted drug delivery aims to direct highly cytotoxic drugs solely to cancer cells, minimizing "off-target effects" on healthy tissues and reducing severe side effects.

Uniform nanoparticles, precisely fabricated via confined dewetting, ensure consistent drug loading, controlled release kinetics, and predictable biodistribution through mechanisms like the enhanced permeability and retention (EPR) effect, where nanoparticles preferentially accumulate in tumor tissue. This precision allows for therapeutic doses directly to tumors, improving efficacy while significantly reducing systemic side effects and improving patient outcomes. Emerging trends include the use of hydrogels combined with nanoparticles for localized and sustained drug release, and the integration of specific peptides like iRGD for enhanced tumor penetration. The precision offered by uniform nanoparticles aligns perfectly with personalized medicine, accelerating treatments tailored to individual patient profiles.

Pioneering a Greener Future: Sustainable Nanomaterials for Environmental Stewardship

Beyond healthcare, confined dewetting presents a compelling pathway towards more sustainable and environmentally responsible nanotechnology, addressing critical global challenges in pollution and resource management.

Cost-Effective, Low-Waste Synthesis

A significant advantage of confined dewetting is its inherent simplicity, cost-effectiveness, and low-waste nature. Unlike many traditional nanoparticle production methods that are "expensive and complex" and often generate considerable waste, confined dewetting offers a "straightforward route" to high-quality nanoparticle fabrication. This aligns seamlessly with the principles of "green synthesis," which emphasizes eco-friendly methods that minimize hazardous chemicals, reduce energy consumption, and generate less waste. By significantly reducing material waste and simplifying the fabrication process, confined dewetting facilitates the large-scale, economically viable production of eco-friendly nanomaterials.

Environmental Monitoring and Remediation

The highly sensitive sensors enabled by confined dewetting have direct and profound applications in environmental monitoring. They possess the capability to detect "minute traces of harmful pollutants like lead in drinking water", paving the way for more effective environmental surveillance and early warning systems. This level of sensitivity allows for the identification of contaminants at concentrations far below what was previously detectable, enabling intervention before pollutants reach critical, widespread levels. This shifts environmental monitoring from reactive clean-up to proactive prevention.

Beyond mere detection, "nanoconfinement effects" are being explored in advanced water treatment technologies. Confining nanomaterials inside porous scaffolds or substrates significantly improves "decontamination efficiency, such as enhanced adsorption capacity, reaction kinetics, stability, and selectivity".The precision and uniformity offered by confined dewetting could play a crucial role in synthesizing the high-quality, consistently performing nanomaterials required for such advanced environmental remediation systems.

The AI Nexus: Accelerating Nanoparticle Synthesis

The convergence of confined dewetting with artificial intelligence (AI) and machine learning (ML) promises to further accelerate the pace of nanoscale innovation, enabling smarter, faster, and more efficient nanoparticle synthesis.

Smarter and Faster Synthesis

Artificial intelligence, particularly machine learning and deep learning techniques, has emerged as a powerful tool to optimize nanoparticle synthesis processes by analyzing complex experimental data and predicting ideal synthesis parameters. Traditionally, optimizing nanoparticle synthesis relies heavily on "labor-intensive trial-and-error experimentation," which is time-consuming and inefficient. AI offers a data-driven approach, capable of uncovering hidden, non-linear relationships between various synthesis conditions and the final characteristics of the nanoparticles.

While the provided data does not explicitly detail AI's direct application to confined dewetting, the method's inherent simplicity, reproducibility, and the clear influence of parameters make it an ideal candidate for AI-driven optimization. AI models could be trained on experimental data from confined dewetting to predict the optimal combination of parameters to achieve specific nanoparticle sizes, shapes, and distributions with unprecedented efficiency, significantly reducing experimental time and cost.

Predictive Capabilities and Automated Discovery

Beyond optimizing existing processes, AI provides powerful predictive tools for discovering entirely new nanoparticle materials and optimizing their design. Machine learning models can analyze vast datasets to forecast outcomes for novel designs, drastically reducing the reliance on laborious physical experiments. Generative AI models can directly design novel molecular structures and propose cost-effective synthesis pathways, leading to "new-to-nature molecules tailored for specific applications".

When integrated with automated laboratory systems, AI enables a "closed-loop approach" that combines computational modeling with real-time feedback, allowing for continuous refinement of nanoparticle production, ensuring consistency and significantly reducing human error. This represents a paradigm shift from traditional, manual experimentation to AI-driven, high-throughput material discovery and synthesis.

Powering Tomorrow: Advancements in Energy Storage

The demand for enhanced energy storage solutions - from high-performance batteries to rapid-charging supercapacitors- is critical for modern electronics, electric vehicles, and renewable energy grids. Confined dewetting offers a promising pathway to synthesize superior electrode materials for these applications.

Enhanced Electrodes for Supercapacitors and Batteries

Nanomaterials are crucial for next-generation energy storage devices due to their unique properties, such as extremely large surface areas and very short internal diffusion paths. These characteristics allow them to overcome the limitations of bulk materials in ionic or electronic conductivities, which often restrict charge and discharge rates. Furthermore, nanomaterials can "withstand much greater mechanical deformation during charge/discharge cycling," a critical factor for long-term device stability and lifespan.

Confined dewetting's ability to produce uniform metal nanoparticles is highly beneficial for synthesizing better electrodes for both supercapacitors and batteries. For supercapacitors, which prioritize power density and rapid charge/discharge kinetics, uniform nanoparticles can significantly enhance the kinetics of ion and electron transport at the electrode/electrolyte interface. This leads to improved capacitance retention and stability, even at high operational voltages, directly addressing issues like poor rate performance and cycling deterioration. For batteries, uniform nanoparticles can mitigate critical issues such as volumetric changes during charge-discharge cycles and enhance the kinetics of conversion reactions, thereby improving long-term capacity retention and overall safety. The precise control offered by confined dewetting allows for tailoring the properties of electrode materials, such as nickel oxides/hydroxides, for optimal performance.

Reaching for the Stars: Ultra-Stable Materials for Space Exploration

The extreme conditions of outer space—intense radiation, vast temperature fluctuations, and micrometeoroid impacts—demand materials with unparalleled stability and resilience. Confined dewetting holds speculative but significant potential in this frontier.

Resilience in Extreme Environments

Space exploration necessitates "radiation-hardened (rad-hard) electronics" and materials designed to withstand high intensities and long durations of radiation, preventing performance degradation and catastrophic device failure.Exposure to radiation can cause significant material degradation, making components brittle, altering their conductivity, and leading to long-term damage. Lightweight, durable, and radiation-shielding nanomaterials are actively being explored as advanced solutions for space applications.

While direct links between confined dewetting and radiation hardening are not explicitly detailed in the provided data, the method's proven ability to produce "pure and stable nanoparticles" with "high density, low size variation, and high purity" makes them ideal candidates for integration into advanced nanocomposites or protective coatings. For instance, the integration of uniform nanoparticles like graphene and carbon nanotubes into polymers has already proven effective in improving shielding properties and material stability against radiation. Confined dewetting could provide the consistently high-quality, uniform nanoparticles needed for such radiation-resistant and ultra-stable materials.

Next-Generation Satellite Sensors

The precision and uniformity achieved by confined dewetting, which are critical for creating highly sensitive sensors, could be directly applied to develop more robust and high-performance satellite sensors. Current hyperspectral sensors in satellites, such as Orbital Sidekick's HEIST, are capable of detecting electromagnetic radiation beyond visible light, providing detailed spectral data for Earth observation, environmental monitoring, and geological surveys. The long-term reliability and efficacy of such sensors in space depend critically on the stability of their constituent metal nanoparticles, particularly their resistance to aggregation and degradation in diverse and harsh environments.

By producing highly uniform and stable metal nanoparticles, confined dewetting could enable the synthesis of advanced plasmonic structures for satellite sensors that offer enhanced spectral resolution, improved signal-to-noise ratios, and significantly extended operational lifetimes in the harsh space environment.

Democratizing Nanotech: Lowering the Entry Barrier for Innovation

Perhaps one of the most significant implications of India's confined dewetting breakthrough is its potential to democratize access to advanced nanofabrication, fostering a new wave of innovation across the globe.

Accessibility for Startups and Small Labs

Traditional nanoparticle production methods, particularly those requiring complex lithographical processes, are inherently "complicated and expensive".They demand significant capital investment in specialized equipment and highly skilled personnel, creating substantial financial and infrastructural barriers to entry.

Confined dewetting, however, is presented as a "simple, cost-effective process" that can be implemented on a large scale. Its ability to achieve precise control and uniformity without the need for complex lithographical techniques means that smaller research labs, academic institutions with limited budgets, and nascent startups can now engage in cutting-edge nanoparticle research and development. This significantly reduces the financial and infrastructural hurdles that have historically constrained innovation in the nanotech sector.

Fostering a New Wave of Research and Entrepreneurship

By making advanced nanofabrication more accessible, confined dewetting is poised to stimulate a broader ecosystem of innovation. More entities, previously excluded due to prohibitive costs, can now experiment, develop, and commercialize novel nanomaterial applications. This could lead to a proliferation of new startups, diverse research initiatives, and unexpected breakthroughs in areas not yet fully explored. The inherent "simplicity, scalability, productivity, and cost-effectiveness" of this method are key drivers for its exploitation in micro/nanotechnology, promising a more inclusive future for nanoscale science.

What Happens Next? Future Outlook

The confined dewetting breakthrough from India represents a significant leap forward in nanoscale innovation, offering a versatile, cost-effective, and scalable method for producing uniform metal nanoparticles. Its potential to revolutionize fields from medicine and environmental science to energy and space exploration is immense. However, like any nascent technology, its full impact and trajectory will depend on continued research, development, and strategic implementation.

The Road Ahead

The immediate future will likely see intensified efforts to optimize the confined dewetting process for even finer control over particle characteristics and to expand the range of materials and substrates that can be processed. Further research into the precise interplay between PDMS properties, metal film characteristics, and heating parameters will be crucial. The integration with AI and automated systems will undoubtedly accelerate this optimization, moving towards fully autonomous nanoparticle synthesis platforms. Commercialization efforts will focus on scaling up production for industrial applications, particularly in the most promising sectors like diagnostics and energy storage.

India's Nanotech Leap

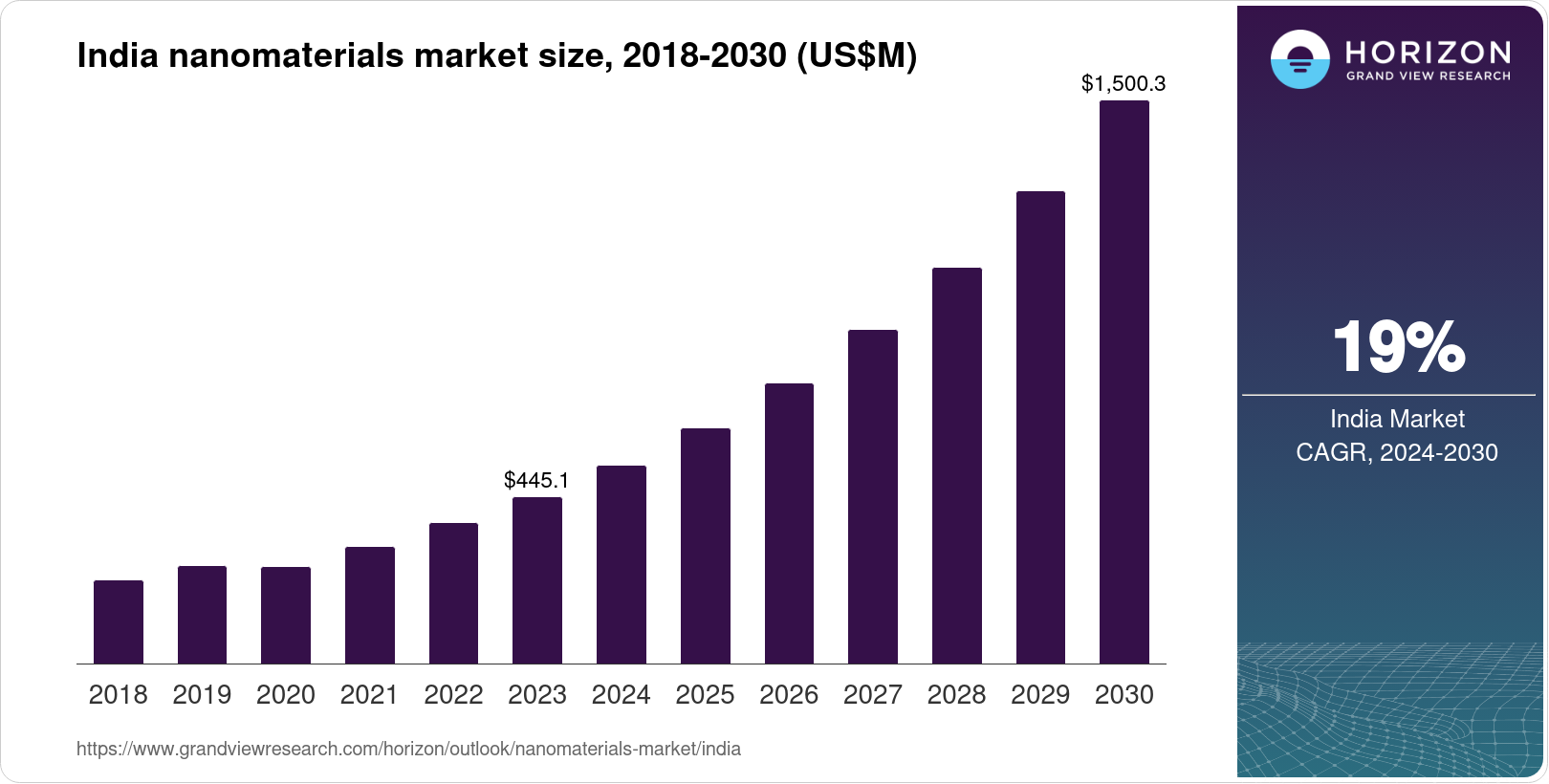

India's breakthrough in confined dewetting stands as a powerful testament to the nation's burgeoning scientific prowess and its capacity to drive global innovation. By offering a fundamentally simpler, more cost-effective, and highly precise method for fabricating uniform metal nanoparticles, this advancement transcends mere technical improvement; it represents a paradigm shift in how nanoscale materials can be produced and utilized. From enabling ultra-sensitive disease detection and targeted drug delivery to fostering eco-friendly manufacturing, enhancing energy storage, and paving the way for more resilient space technologies, confined dewetting is poised to reshape industries and improve lives worldwide. More profoundly, by lowering the historical barriers to entry in nanotech research, India has not only contributed a significant scientific tool but has also ignited the potential for a more inclusive and globally distributed future of nanoscale innovation. This is not just a scientific achievement for India; it is a catalyst for a new era in global nanotechnology.

Sources

Times of India, ETV Bharat, PMC NCBI, ResearchGate, News-Medical.net, Indian Express, MDPI, Eaton, Imec, ISS National Lab, UCF Online, StemRad, DSpace@MIT, IJSET, World Economic Forum, AniLocus, IISc Bengaluru- Nature Nanotechnology, 2025, Grand View Research, ACS Publications, Frontiers in Pharmacology, RSC Publishing, ResearchGate.